A lot of work has been completed, but I lack that exemplary feeling of joy

after completing a section or part that I normally get. I suppose this felt

more like a lot of small chores that needed to be done in order for me to

move on to those larger tasks. Don't get me wrong, this was still a lot of

work.

Tues 13th - 1.75hrs- Started upper forward fuselage section

Wed 14th -0.5hrs- Measured for antenna install, made

spacers for step

Thur 15th -1.0hrs- Worked on upper fuselage, bent panels,

drilled out holes

Sat 17th -6.5hrs- Made antenna doublers, drilled skin for

antenna install, primed parts, installed stainless steel heater boxes, made

clips for wiring conduit

Sun 18th -5.25hrs- Installed side panels, installed steps

I didn't get very far on the upper forward fuselage section. I just clecoed

parts, drilled holes, made a stiffener out of extrusion, and then clecoed to

the aircraft.

I ordered and installed the stainless steel

heater boxes instead of Van's aluminum ones. Stainless Steel's thermal

conductivity, or K-value, is a fraction of aluminum's; meaning that the

stainless steel heater boxes will insulate the tunnel from the heat better than

aluminum. Hopefully, this keeps the tunnel's heat cooler than what it would

originally be. Also, in the event of an engine fire the aluminum would just

turn into a puddle from the heat but the stainless steel would still be

there. I also installed the boxes with a high temp silicone gasket (note the

white tube in the pic below was shipped with the boxes) and some 3M fire

barrier sealant around the edges to help keep the fumes out.

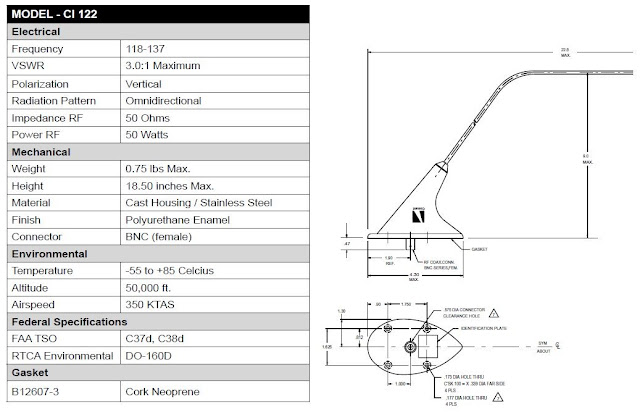

The Com Antennas Install has begun!

See my previous post for what my plan is for these antennas as well as

dimensions and a discussion on the doubler sizing. I made the doubler first,

per the dimensions I show on the previous post, and then I drilled out the

rivets on the outboard frame since they will be incorporated into the doubler

install. I match drilled the existing holes into the doubler and then match

drilled the doublers holes to the skin.

I then drilled the large center hole in each part,

deburred, dimpled, and primed everything. Here is a pic looking down and

forward on the left hand installation location.

I then drilled the large center hole in each part,

deburred, dimpled, and primed everything. Here is a pic looking down and

forward on the left hand installation location.

The doublers and shims dimpled and primed.

The antenna clecoed in place.

I finally got around to installing the side vent doors.

The step install.

I am installing these a little differently than what the plans say to do. I am using 1/4in hardware instead of #10 and I am installing it at angle instead of straight up and down. This will allow removal of the bolt in the future through the access panels I will be installing in the luggage compartment floor. I also made spacers from delrin rod to insert into the step tube to reinforce the tubing and prevent it from being deformed while tightening the bolt. I made them from delrin because it's cheap, I think it was around $3 for the rod I bought, and it wont cause dissimilar metal corrosion sitting inside the step.

I made a makeshift insertion and positioning tool from pvc and safety wire.

The step installed. It's a little scratched from sliding it in place, but I can touch that up later.

View from the outside and the "shin protector" is installed.